Bi-Scale Appearance Fabrication

- Yanxiang Lan1,2

- Yue Dong2

- Fabio Pellacini3,4

- Xin Tong2

- 1Tsinghua University

- 2Microsoft Research Asia

- 3Dartmouth College

- 4Sapienza University of Rome

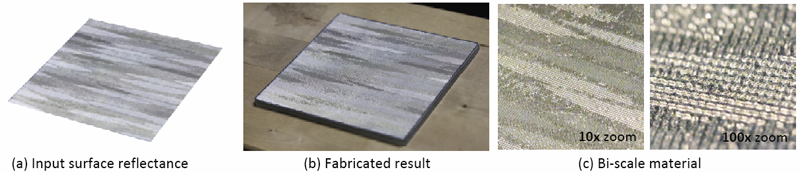

Given an input surface reflectance (a) with anisotropic BRDFs and per-point shading frame variations, our system prints a bi- scale material (b) to reproduce the input surface reflectance. The bi-scale material consists of a small scale height field covered with isotropic BRDFs as shown in (c).

Abstract

Surfaces in the real world exhibit complex appearance due to spatial variations in both their reflectance and local shading frames (i.e. the local coordinate system defined by the normal and tangent direction). For opaque surfaces, existing fabrication solutions can reproduce well only the spatial variations of isotropic reflectance. In this paper, we present a system for fabricating surfaces with desired spatially-varying reflectance, including anisotropic ones, and local shading frames. We approximate each input reflectance, rotated by its local frame, as a small patch of oriented facets coated with isotropic glossy inks. By assigning different ink combinations to facets with different orientations, this bi-scale material can reproduce a wider variety of reflectance than the printer gamut, including anisotropic materials. By orienting the facets appropriately, we control the local shading frame. We propose an algorithm to automatically determine the optimal facets orientations and ink combinations that best approximate a given input appearance, while obeying manufacturing constraints on both geometry and ink gamut. We fabricate the resulting surface with commercially available hardware, a 3D printer to fabricate the facets and a flatbed UV printer to coat them with inks. We validate our method by fabricating a variety of isotropic and anisotropic materials with rich variations in normals and tangents.

Keywordsfabrication, bi-scale, SVBRDF, local frame, normal map DownloadsBibTex

@article{Lan:2013:BAF,

author = {Lan, Yanxiang and Dong, Yue and Pellacini,

Fabio and Tong, Xin},

title = {Bi-Scale Appearance Fabrication},

journal = {ACM Trans. Graph.},

issue_date = {July 2013},

volume = {32},

number = {4},

year = {2013},

publisher = {ACM},

address = {New York, NY, USA},

}

|

AcknowledgementsThe authors would like to thank Jiaping Wang, Yingqing Xu and Baining Guo for inspiring discussions and Jingyong Zhou for operating the physical fabrication pipeline. 3D printing service was provided by Beijing Innovo Technology Co. LTD. and flatbed UV printing was provided by Beijing Aojet Industrial Co. LTD. The authors also want to thank Stephen Lin for paper proofreading. Thanks to Toler-Franklin et al. [2007] and Lawrence et al. [2006] for their generously shared datasets. The authors are grateful to the anonymous reviewers for their helpful suggestions and comments. Fabio Pellacini was partially supported by NSF (CCF-0746117), Intel, and the Sloan Foundation. RelatedPrinting Spatially-Varying Reflectance for Reproducing HDR Images |